Cad For Textile Software

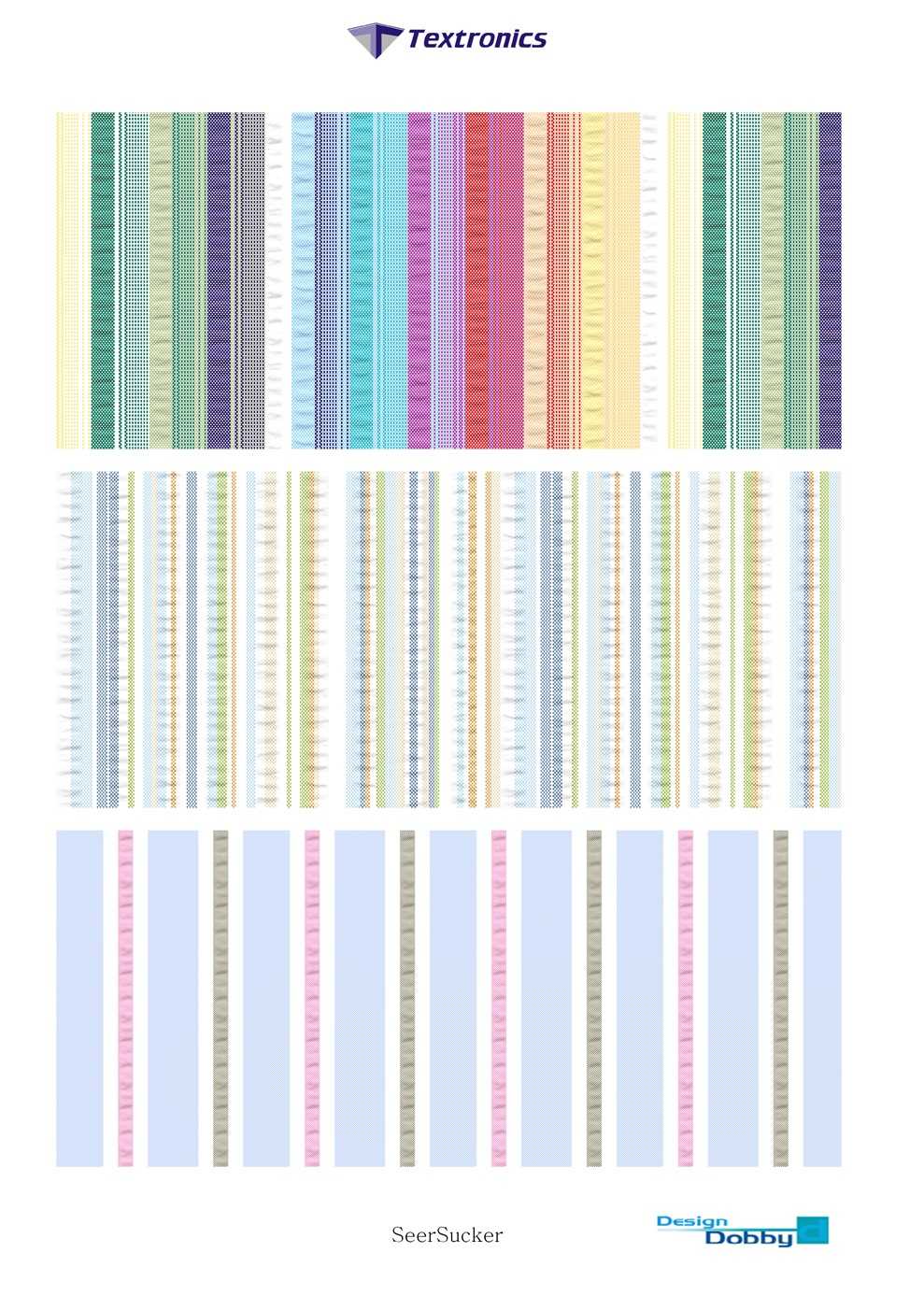

Use of CAD & IT IN TEXTILE. Use of CAD & IT IN TEXTILE. Today, with the introduction of CAD and its many software capabilities. Development of graphical software for the design of fabrics. Jan 11, 2014 - Today, with the introduction of CAD and its many software capabilities, the possibilities are endless. The entire process of designing a fabric is revolutionized. Where previously designers used to labor over graph paper and stencils, now they simply have to play with a mouse or stylus pen to come out with.

Is the contraction which stands for Computer Aided Design. CAD or Computer Aided Design has brought a revolution in the Textile industry, especially in apparel industry.

The time consuming and cumbersome process of textile designing has been made easier by CAD. Now thoughtful and innovative designs are available to the textile designers and textile manufacturers at the click of a mouse. Here, mainly and marker is created by computer which ensures accuracy of the pattern and marker which ensure defect less cutting & defect less garments. Software Used in the factory: • Winda Pattern Design System and Garment Grading System • Winda Garment Marker System • Winda Garment File Format Converter Machine used In Pattern and CAD Section: • Winda pattern cutter • Winda plotter Figure- Winda Pattern Cutter. Working Procedure of CAD Section: • In CAD section at first the pattern put on the digitizer to take clear image of the pattern part inside the CPU. • After making all required size patterns using the software pattern parts are aligned in the mini marker. Then it is sent to CPU of CPM section for approval & checking the length & width of marker and pattern parts alignment.

Template Label 103. • After getting approval from CAD section then printer is used to print out the whole real marker then this marker as well as mini marker are provided to the CAD section for. Advantages of CAD Software in Apparel Industry: • This easy to operate designing system- CAD has many advantages.

• The expense and time is reduced in a considerable manner when compared to the laborious manual work of designing. • Designing can be done from anywhere as the customers are able to control the process from remote locations as well. • The data can be easily stored, transmitted, and transported through computer files. • The designs can be easily customized and personalized as corrections and editing can be done at any time without significant delays or cost increases. • The don't need to produce swatches all the time as they can now see how a particular fabric or garment looks in different colors and shapes on computer screen itself. About Author: Mohammad Sajjadul Karim Bhuiyan BGMEA University of Fashion and Technology Email: You can also like: • •.